Paintwraps

Paintwraps

Justin is an Avery Specialist and 3M Certified graphics instructor who worked out of the New York City area for over 11 years and now, for the past 4 years, out of Amsterdam, the Netherlands. Justin has installed graphics on buildings, windows, floors, walls and glass but full coverage vehicle wraps have become his specialty. Justin created the Mutoh School of Wrap hands-on workshop. From this workshop came the impetus to make Technique and Tips: Vehicle Graphic Installations. This DVD is sold at www.learntowrapcars.com, Sign Warehouse and is offered to all Mutoh owners via streaming video at www.carwraps101.com. For more information on paintwraps, visit www.paintwraps.com.

About three years ago, I started installing wraps in Europe because I moved to Amsterdam so that my wife could be close to her family for the birth of our daughter. I made the move thinking that I would simply pick up where I had left off in the U.S. with my wraps business. Over the previous 11 years, I had installed almost 2,000 wraps-every one of them full-print graphics. After making some contacts in the Netherlands, I got hired for my first job, a full wrap on a van, including roof and bumpers.

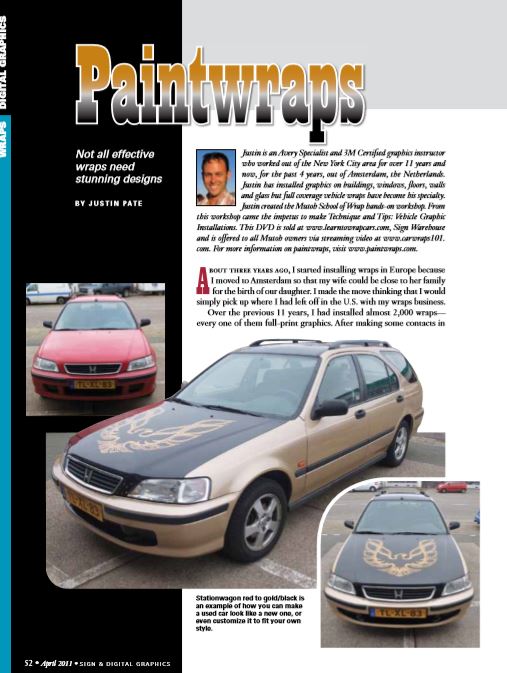

When I showed up to the job, I opened the box and saw a roll of yellow film and some blue vinyl text. I thought, "What was this?" I looked at the layout and saw a yellow van with blue text/shapes. I looked at the van, and it was silver. My job was to make the van yellow and put the text on over top. Piece of cake, I thought. Usually, this vehicle in the U.S. would take me around six hours to complete. Well, when I got done 15 hours later, I wasn't thinking piece of cake anymore. Yet, what I was thinking wasn't that it took way longer than normal but that paintwraps are quite possibly cooler than HBO's Deadwood. I had just been introduced to paintwraps, and my perspective on wrapping vehicles hasn't been the same since.

Changing the color of a vehicle with a single-color cast film had been used for years in Europe. These single color films, like Avery 900 and 3M's 100 series, get the job done in terms of changing the color but they have several drawbacks compared to today's wrap films. They are very thin (around 2 mm) with aggressive adhesive. Thin film shows air egress channels, so it's not built in.

This combination makes installations challenging and slow. Also, the single-color cast films have more of a plastic-like appearance than paint.

Right before I moved to Amsterdam, the major film manufacturer divisions in Europe started to build a lamination layer into the single-color film at the factory. The lamination layer gave the film an added thickness, which allowed for air egress and repositionable technology to be added to the adhesive layer. More importantly, the lamination layer gave the single-color film the exact appearance of paint. With the addition 54 • April 2011 •SIGN & DIGITAL GRAPHICSof the lamination layer, paintwrap film was born, and a whole new wrap world came to life.

The first projects to use paintwrap films were for large fleet jobs. The results were well received by both clients and installers. The main reason for this was the vehicle wrap industry finally had a product that looked like paint and it was easier to apply than the previous single-color cast films. This meant that paintwraps could be sold as a legitimate form of paint replacement.

Why is this a big deal? Simply, time and money. But, to better explain, here are three specific reasons. First, a paintwrap protects the original paint of the vehicle from scratches and UV damage. This significantly raises the resale value of the vehicle. Second, a paintwrap can be installed by two professional installers in a day, so the turnaround is quicker than traditional painting. Also the removal of the film is generally even quicker than the install. And third, paintwraps come with between 20-30 standard colors, and custom color matching can be done for orders over a certain amount. In short, the vehicle is out of service for less time, has a higher resale value often above and beyond the cost of a paintwrap and there is a wider selection of colors.

This year, Pate plans on launching an online streaming instructional video platform called The Wrap Institute, which will be a key resource for learning solid installation techniques. Also for 2013, Croftgate USA will launch the Wrap Care JP After Care product series that he helped develop (JP stands for Justin Pate). The products are made to help keep wraps looking brand new throughout life of the install. When he is not teaching or wrapping he loves to spend his time with his wife Beertje and daughter Tigerlily.

This now means that a leasing company can sell paintwraps and make a profit. When a term for a lease is up in three years, the paintwrap is removed and a car with a pristine, original paint job is sold. Cab companies can now wrap their entire fleet instead of painting them. Military vehicles can be wrapped matte green. Trains can be paintwrapped instead of covered with traditional paint. Imagine how much quicker and cost-effective it is to wrap a train instead of painting it. Plus, for trains, an anti-graffiti lamination is often used, so when they are tagged or spray painted by graffiti artists, the graffiti can be washed off. This dramatically cuts down on maintenance costs and preserves pristine trains. Subway cars can be wrapped inside and out. Car dealerships have a wider selection of colors including finishes like metallic or matte.

After installing paintwraps for about a year, I talked to an installer friend of mine about it in the States. He thought it was interesting and said that black matte wraps were getting popular. I told him that black matte was, in fact, paintwrap film and to try it out on his car. He did, and, like I thought on my first one, he said it was going to be a piece of cake. "All I have to do its cut this roll of black matte into pieces and slap it on, right?"

15 hours later he called me up, dismayed, to say that he was still working. So, why are paintwraps harder to install than full print wraps? Several reasons:

1. There is no margin for error both in terms of cleaning and finishing. A tiny spec of dirt under a full-print wrap tends to get lost in the design, but for a paintwrap, even the tiniest bump stands out like a sore thumb. This means more time has to be spent cleaning the vehicle and workspace. In terms of installation, a section on the vehicle can just about be finished and one bad cut means that it has to be replaced. A bad cut stands out on a paintwrap just as much a tiny spec of dirt.

2. It's seamless. There are no patches or relief cuts. Every section on a vehicle must be done in one piece, which means the installer must have professional-level skills. Also, hardware that can be worked around smartly for a full-print wrap more often than not has to be removed for a paintwrap.

3. Durability. With a lot of full-print wraps, the duration of the wrap can vary from one week to a month to three years. Paintwraps generally are expected to last three to four years, and installing with durability takes more time and skill.

4. Wrap farther. Normally with a full-print wrap, the outer surface area is covered with as little folding into the inside. But with paintwraps, the film must be applied farther into the vehicle, which takes more time.

All of this adds up to a longer install. Yet, on the flip side, there's no printer, no laminator, no files, designer or production team. With paintwraps, it's choose a color, section up a roll of film and wrap.

How big is paintwraps in Europe so far? Well, I've been working here for three years now and out of the 350 cars I've wrapped, only 10 have been full-print wraps. Everything else is paintwraps.

The taxi cabs in Berlin and Stockholm, the government vehicles, trains and subways in the Netherlands, BMW and other car companies. Black matte wraps are popular in the States, but this is just the tip of the iceberg. Now that Avery is introducing their Supreme Wrapping film and 3M has their 1080 film available in the states, a full spectrum of paintwrap colors will be available, which will enable the concept to take hold.

Years ago, one of my big clients at the time said that he thought 30 percent to 40 percent of all cars would be wrapped by 2015. I wanted to believe him, but just couldn't see how full-print wraps could get that big-maybe five percent of all cars, which even then is a staggering amount. Yet, after seeing paintwraps and its potential, I am starting to believe the vision of my old client.

So, when I talk to my colleagues about whether paintwraps will be huge in the U.S., I tell them you never know, but, in my opinion, it's going to be bigger than my wife's belly the day she gave birth to our daughter.