Heavy Metal

Heavy Metal

In 1996, when I started wrapping in NYC, the companies I worked for sent me premium cast films with air egress and repositionable technology for walls, floors, cars, buses and trailers. Kind of like in Lord of the Rings, "one ring to rule them all," it was "one film to wrap it all."

When I moved to Amsterdam in 2007 and started traveling worldwide teaching workshops in 2011, I was quickly educated on the differences between cast and calender films in terms of full wraps and the subtle yet significant differences between a large group of worldwide wrap film manufacturers. Each brand is like a person with unique characteristics. If you treat everyone exactly the same you are going to get mixed results, some people will like you, some not so much. If you learn to see the unique charac- teristics of each person and adapt, most everyone will like you. The trick of how to do this with all the different worldwide wrap films, despite the wide variety of colors and finishes, is to do the black and white. What is it to do the black and white? Simply, read the fine print of the product bulletins, absorb specific information from a product video or go to a chat forum and ask before you wrap. Here are some examples:

EUROPE

"I think the biggest trend right now is how wide and varied the applications for paint wrap films are becoming," says Justin Pate of Justin Pate Inc., an Avery Dennison specialist and 3M-certified graphics instructor/installer who spe- cializes in vehicle graphic installations. Pate, who is based in Amsterdam, and Bosie, Idaho, says that this is very excit- ing in terms of paint wrapping because it appeals to a wider base of clients and draws talented installers into the industry.

EUROPE

In 2007 in Europe, color change applications were just beginning to emerge on an industry-wide level, which meant new materials coming out every year from a wider and wider range of companies outside the Big Three: 3M, Avery Dennison and Orafol. Companies like Hexis, Arlon, SOTT, APA, Grafitype, KPMF, isee2, Ritrama and Mactac. Some of these companies only make calendar film, which meant having to learn to wrap vehicles in that par- ticular style (significantly different than cast) as well as to understand minor but important differences on how to apply each brand, especially when it came to the adhesive and post-heating.

For example, the first time I wrapped with Hexis film, I was told by the wrap shop who hired me it was a premium cast film from France. With that to go on, I wrapped the car like I normally would any other premium cast film with post-heating only on the areas where the film was stretched more than 10 percent at the end of the day. What a surprise to find the next day major failures, even on edges of flat areas. Was it faulty film or install? No, simply not doing the black and white. Since Hexis was new to the Netherlands, I called a friend who is a 3M tech rep and told him what happened. He explained to me that Hexis had pressure sensitive adhesive, not pressure activated like 3M, Avery Dennison and Orafol. This means any recessed area and-especially edges- must be post-heated as soon as that section was finished-whether a hood, fender or bumper. Waiting until the end of the job is too late. Good to know, so next time I got Hexis wrap film I post- heated right away, even on the edges, and calculated for longer install times based on longer post heating. The final wrap held perfectly.

For fleets in Europe, calender is widely used. In the Netherlands, around six years ago a large company called TBI slotted to wrap their entire fleet with around 150 cars scheduled per year. The first year (early days of color- change films), the best color match and film option was actually Avery Dennison 900 SC (cut vinyl film). One vehicle took two installers around 15 hours to wrap. The next few years, the film was replaced with Mactac Tuning film, which is a calender film. The install is different than with cast as it involves more inlays, edge seal tape for the underside, more post heating and Mold 'n' Hold for the mirrors. However, due to a less aggres- sive adhesive and more manageable thickness (900 SC is 2 mil and Tuning is 4.25) it took one installer 9-12 hours to wrap a vehicle.

This year, the film has now switched to Avery Dennison SWF, which is a pre- mium cast film. This means fewer inlays, less post-heating and now it's one installer in 7-8 hours. What you can see over the years is constant adaptation on the num- ber of installers, techniques used, material costs and brands simply based on doing the black and white. That's why the com- pany that manages this job, Omnimark, is so successful.

WORLDWIDE - WHAT IS CAST?

When I started traveling worldwide for workshops, I was really surprised to see installers who had no clue what cast film was. I was also introduced to more brands outside of the U.S. and Europe like Alltak in Brazil or Teckwrap in China. I even saw installers doing full wraps with films that would never even be consid- ered in the U.S. or Europe like Orafol 651, an intermediate calender cut vinyl film. The wrap companies and installers were not using these films because they liked the challenge (or pain). They use these films due to price point, availability, and, in some cases, lack of seeing the big picture.

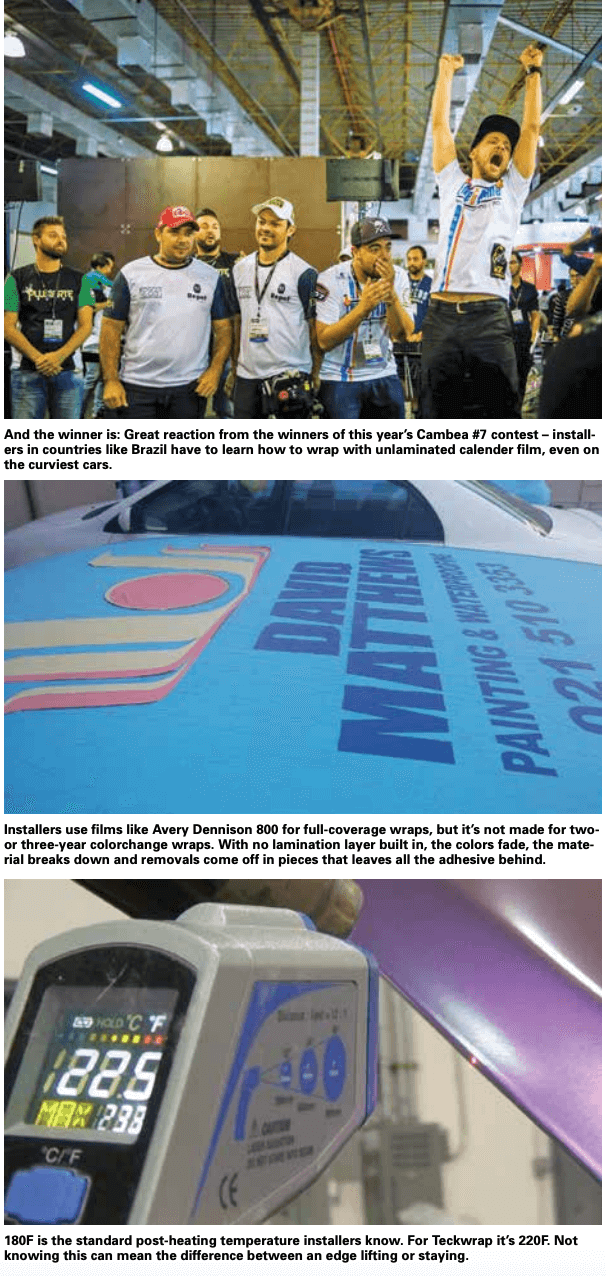

Teckwrap is a calendar film from China that has a lot of cool colors and the company brands itself well. However, an installer may not know that Teckwrap films have a much higher post-heating temperature. With Mactac Tuning film, also a calendar film, the post-heating temperature is 180F while for Teckwrap films its 220F. This is because Teckwrap is a multi-layered film and thicker than standard colorchange calendar films. Not knowing this post-heating temperature can mean the difference between a happy client with a cool color/finish or a redo because of lifting.

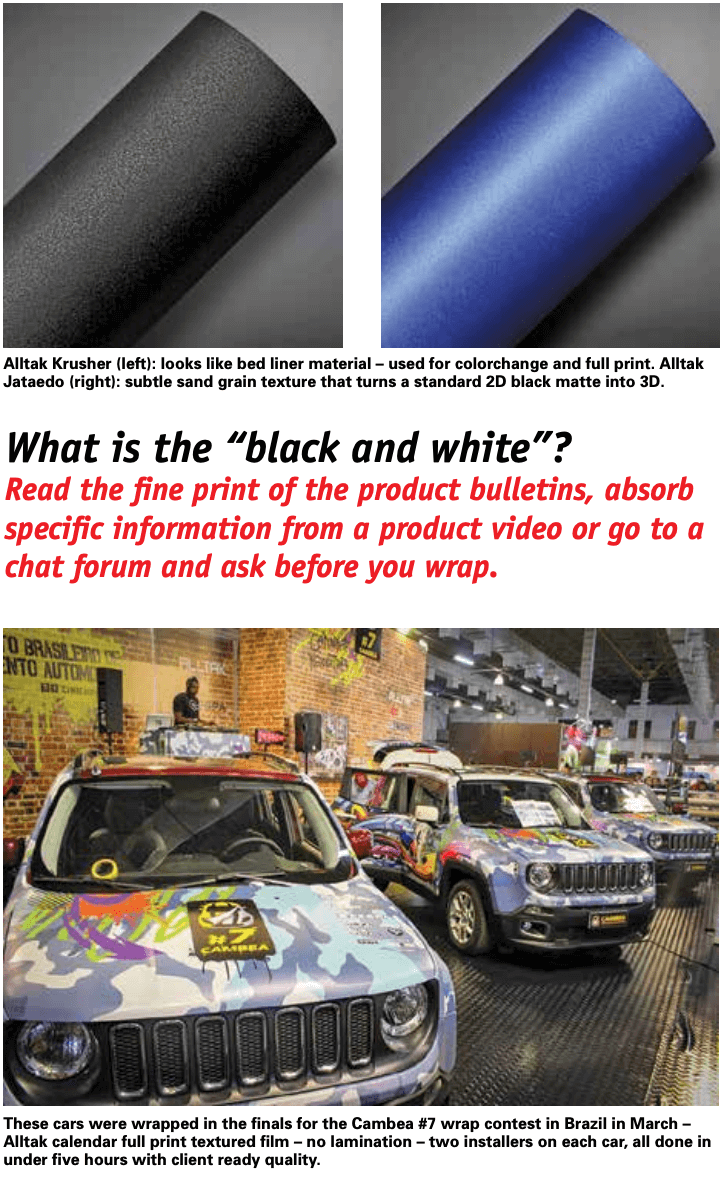

Alltak, a private manufacturer in Brazil, makes calendar full-print and colorchange film with a water-based adhesive that has air egress. One very successful direction they have taken is with textured films that have a medium to heavy sand-like grain (Jateado and Krusher correspondingly). For colorchange films, this texture creates a cool 3D effect either subtle or dynamic. For full-print films, this texture means no solid overlaminate can be applied (this is not a problem because hardly any client in Brazil will pay for lamination). With flat-faced full-print films, no lamination means scratches and fading. Alltak's tex- ture actually helps minimize scratches and fading, which means their unlaminated wraps actually hold up well. Keep in mind that Teckwrap and Alltak, both polymeric calender films, have a 3-5 percent natu- ral shrinkage so be sure to wrap the film around all edges unlike with cast films.

What is most interesting is the use of cut vinyl films for full wraps. These types of films are used primarily because they are often 1/3 to 1/5 the price of premium cast films. Distributors in these low-income counties are afraid of stock- ing premium cast as they may have to eat expensive dead stock so they push budget cut vinyl for full wraps since it is widely used by sign shops. However, what it means is that installs are super difficult, the films do not weather well (no lamination layer built in), the manufacturers do not warranty the install and almost 100 percent of the adhesive stays on the vehicle when the wrap is removed. Here is a great example:

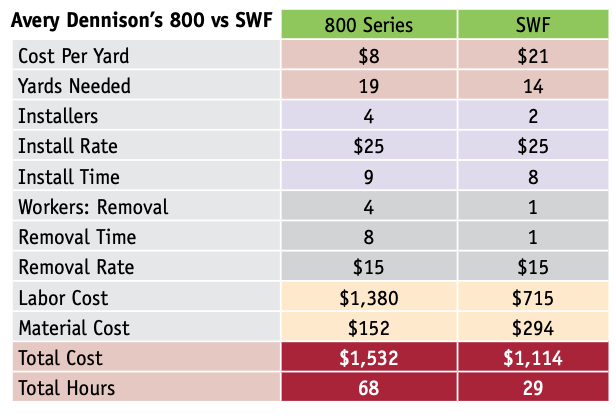

While I was teaching in South Africa this year, a lot of the installers complained about having to use cut vinyl films for full wraps (in this case Avery 800 SC). They said their bosses or customers saw only the material cost on the front end but not long, difficult installs/removals. This got me to think- ing, so after one workshop I sat down with Sarel Kruger, the Avery Dennison rep, did the black and white: numbers on cost of material, install times, number of installers, hourly rate, removal time. The chart above shows the results, and they were shocking.

The material cost was indeed higher for SWF but, since 800 series is only 48 inches wide, more was needed. For the install, to complete the wrap in one day, four installers were needed for 800 series and only two for SWF. The removal was where it got super interesting, especially in terms of the big picture. Four install- ers one day for 800 series, one installer in one hour for SWF.

Based on material cost, installer hours/rates, install and removal time, using SWF over 800 series was almost 33 percent cheaper. The bigger difference was time spent on that one vehicle: 68 hours for 800 series with four installers vs. 30 hours with two installers for SWF.

What does this mean in the big, big pic- ture? 800 series keeps a wrap shop in the one-car-a-day rut while SWF opens the door to volume.

Sarel told me the shops in South Africa that used premium cast vinyl film were the most successful ones with the happiest installers. They bit the bullet on the front end to make big money on the back end. They did the black and white. The companies that felt like they dodged a bullet on the front end were stuck with long, frustrating installs and removals that would test even the patience of Buddha. They didn't do the black and white. Does doing the black and white take time, and is it a little boring? Sure. This is one reason why The Wrap Institute started making video versions of the

product bulletins for the manufacturers.

People would rather watch the info than read it. Wrapping with the new gloss Colorflow for Avery Dennison? Watch the product video first, then wrap. Want to work with a Teckwrap film? Watch the video first, then wrap. If product bulletins or videos don't float your boat, go to The Wrap Society and ask other members for advice. Better yet, call or email the tech rep from that specific manufacturer and ask for the lowdown on that specific material. All these options are free and only take a few minutes. By taking the time to do the black and white for wrap film from Europe or Asia you've never used or deciding to buy premium vs. budget, you will be pleasantly surprised to see a lot of green in your pocket and wild colors on your customer's car that look like paint.